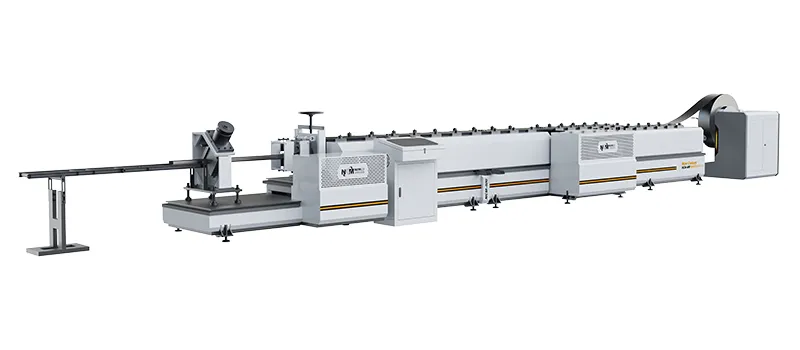

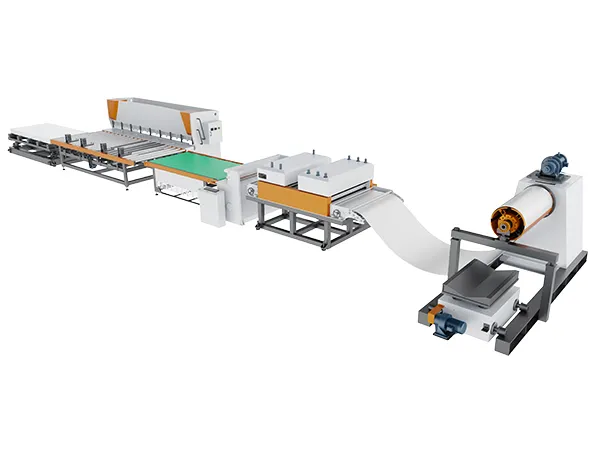

Automatic Steel Door Frame Production Line

Integrated system for automatic production of metal door frames with pre-punched holes

Automatic steel door frame production line achieves the automatic processing of various steel and stainless steel door frames, including one-step frame forming, hole punching, and section cutting, through hydraulic stamping. By employing a pre-punching process, it prevents situations where certain door frames cannot be punched after forming. The steel door frame production line can achieve simultaneously roll forming and storing materials without interruption, ensuring maximum production efficiency of the roll forming machine and overall line efficiency. For material storage, we offer two options: storage device and pit storage method.

| Model | ||

| Material thickness | 0.8~1.8mm,customizable following customer needs | 0.8~2.0mm,customizable following customer needs |

| Production speed | 0~8m/min,adjustable | 0~10m/min,adjustable |

| Material width | 100~400mm,customizable following customer needs | |

| Power | 20-45kW (depending on product configuration) | |

| PLC system | Delta/Siemens,optional | |

| Material storage | Storage device:No need for foundation construction,convenient for subsequent equipment relocation. Pit:Large storage capacity,maximizing the production efficiency of molding machines. | |

- All processes are automated, effectively reducing labor and space requirements.

- Punching tools and cutting methods can be freely combined.

- A complete line can accomplish the forming of door frame upper frames, hinge frames, and lock frames without the need for additional equipment.

- This automatic door frame production line allows for batch production and the forming of frame shapes that are not possible with some bending methods.

Security doors

Security doors Fire-rated doors

Fire-rated doors Healthcare/hospital doors

Healthcare/hospital doors Cleanroom doors

Cleanroom doors

-

-

-

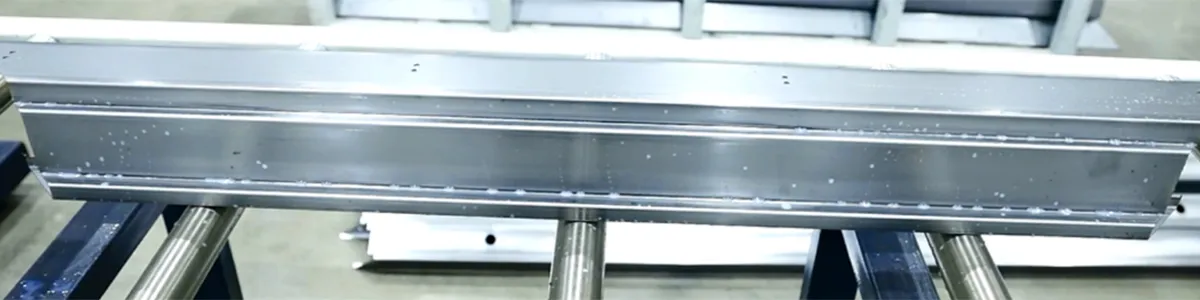

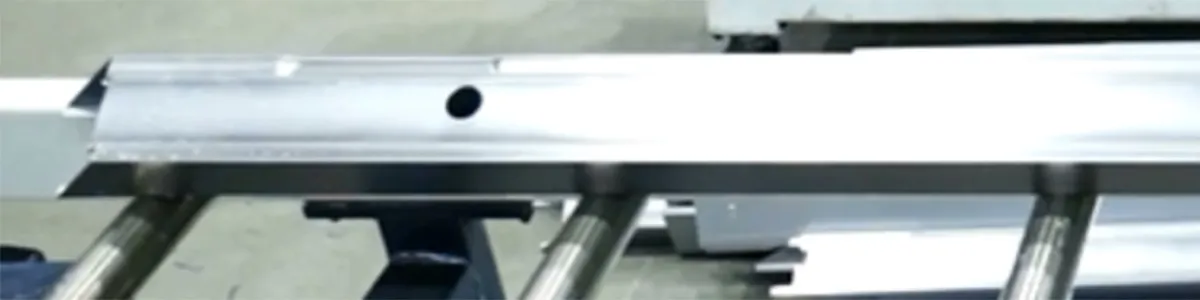

Pre-punching Machine

Independent workstation with independent hydraulic cylinder structure, each stamping station can be controlled independently or used in combination with other stations as needed. If a single one is damaged, it does not affect the use of other workstations.

The stamping method uses hydraulic pressure for greater force and a burr-free stamping surface.

-

-

-

-

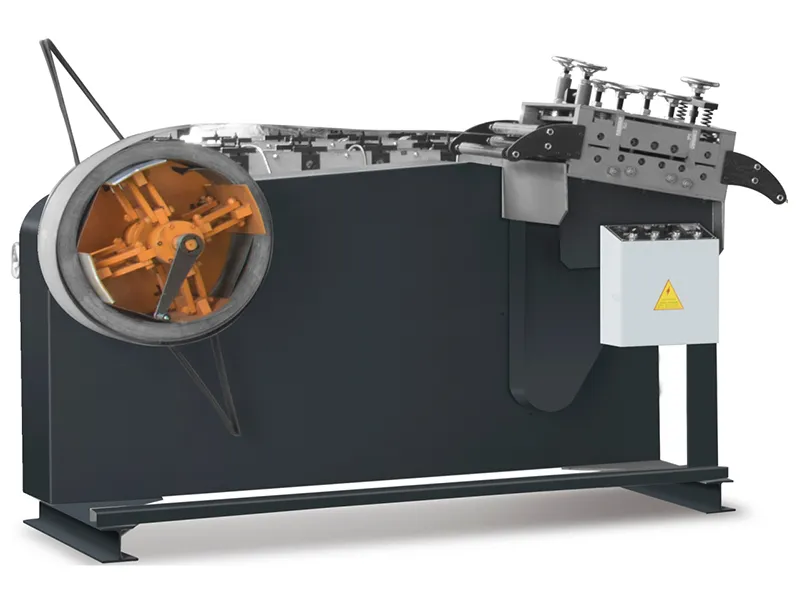

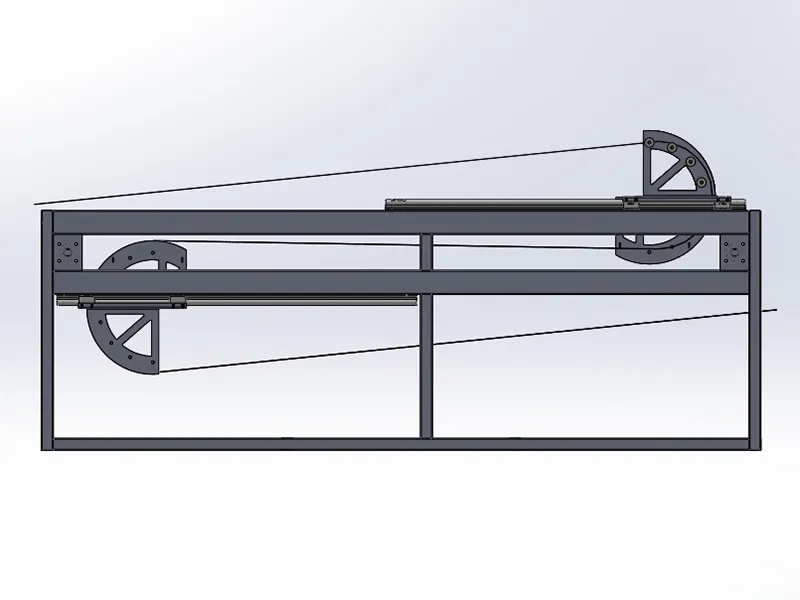

S-Shaped Storage Device

1. Replaced the traditional method of digging pits by adopting an S-shaped material storage structure, allowing the punched coil to be stored first, enabling uninterrupted operation of the forming process.

2. This reduces the initial excavation of foundation pits and facilitates the relocation of subsequent equipment.

-

Roll Forming Machine

Our team of engineers will answer all your questions regarding our metal door machines as well as solutions and services.