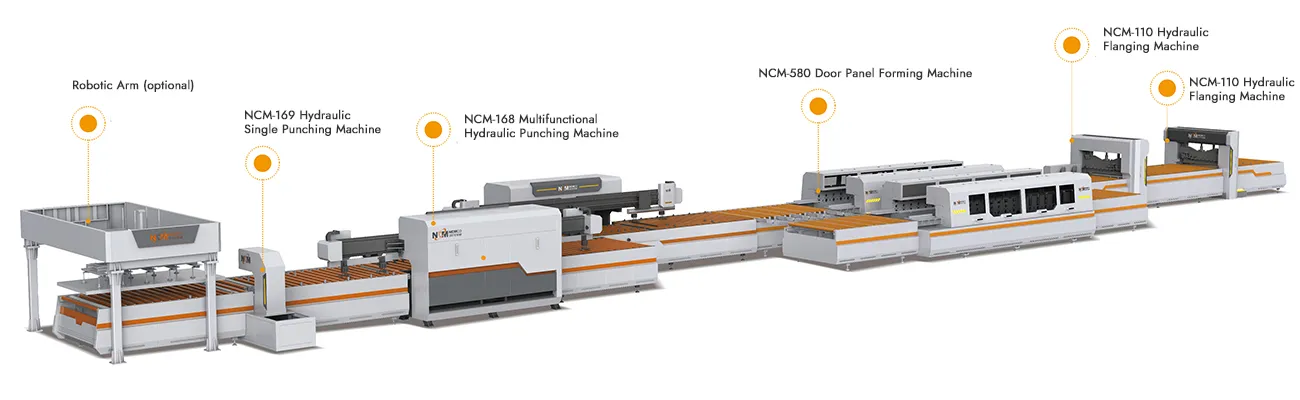

Automatic Steel Door Panel Production Line

Comprehensive metal roll forming line for metal door leaf manufacturing

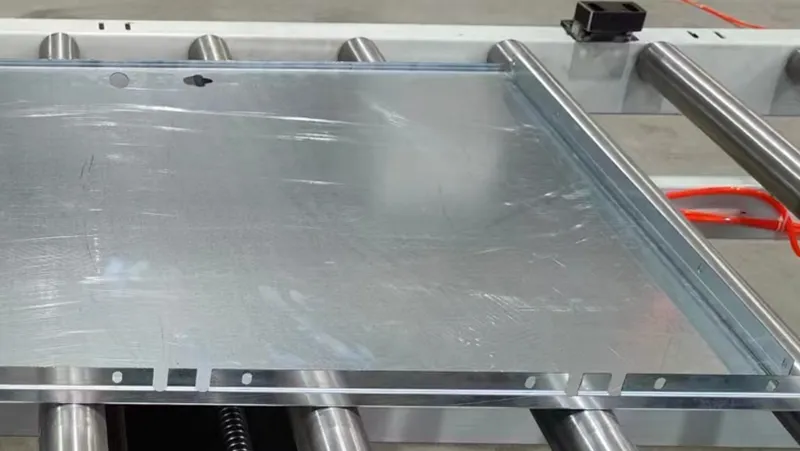

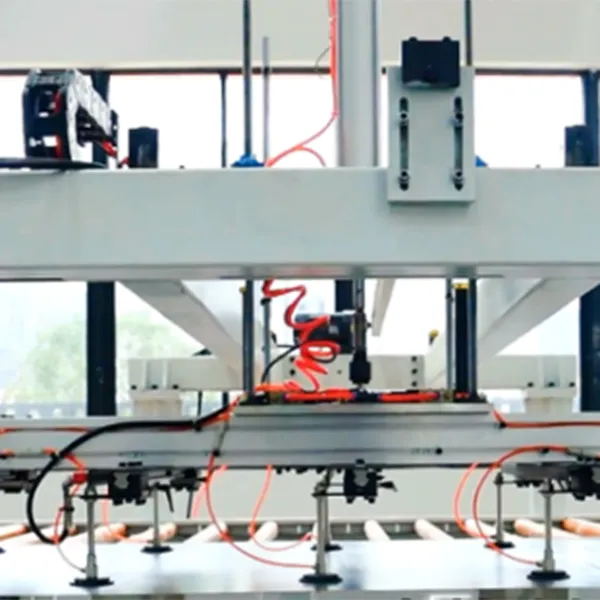

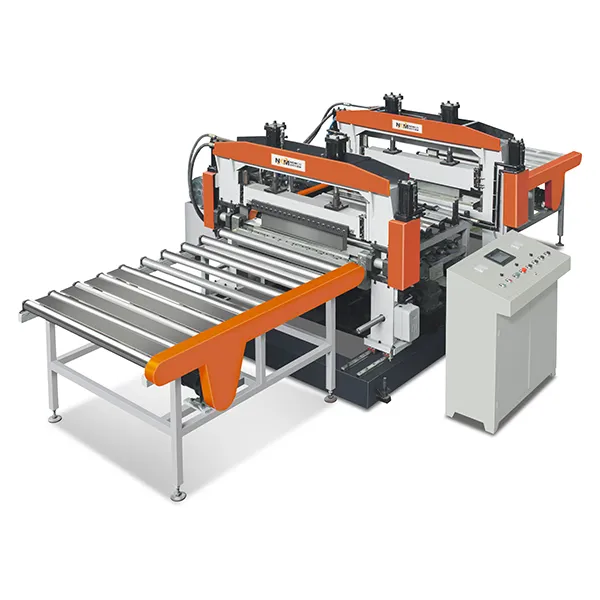

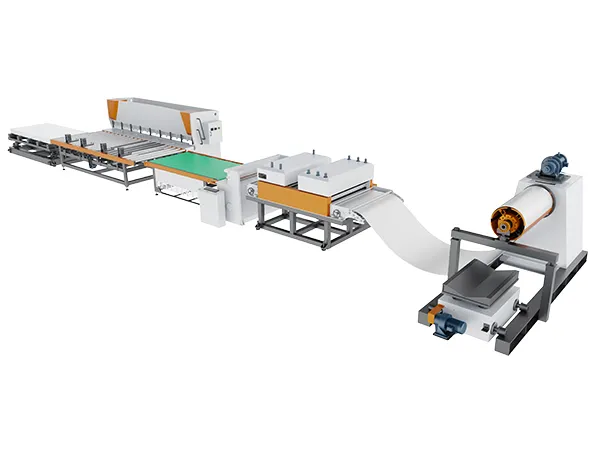

Automatic steel door panel production line utilizes a robotic arm for automatic feeding of materials. By employing the NCM-580 door panel roll forming machine, it achieves one-step forming of the side frames of the door panel. Hydraulic flanging is utilized to shape the top and bottom ends. The door leaf production line can be customized according to process requirements. When selecting the multi-head punching machine for hole punching, extruded hole forming can be performed simultaneously. When choosing laser cutting for perforation, the production line does not require molds and hole positions can be customized as needed.

| Material thickness | 0.5-1.0mm,customizable |

| Material width | 400-1200mm,customizable |

| Production speed | (30-40) S/P |

| Total power | 30-80kW (depending on product configuration) |

| PLC system | Delta/Siemens,optional |

- Multi-head punching machine allows for integrated forming, fast production efficiency, and extruded holes forming at the same time.

- Separate production lines for front and back panels, maximizing production efficiency.

Security doors

Security doors Fire-rated doors

Fire-rated doors Healthcare/hospital doors

Healthcare/hospital doors Cleanroom doors

Cleanroom doors

- Robotic Arm (optional)

- NCM-169 Hydraulic Single Punching Machine

- NCM-168 Multifunctional Hydraulic Punching Machine

- NCM-580 Door Panel Forming Machine

- NCM-110 Hydraulic Flanging Machine

-

-

-

Roller Conveyor

1. Servo motor ensures stable running, interference free, and multiple control modes.

2. The rollers are made of high quality materials, providing lose noise, strong load bearing capacity, stable running and wear resistance.

3. The machine body adopts a "pull welding" process, which further enhances the stability of the connections and improves the overall lifespan of the machine

-

Our team of engineers will answer all your questions regarding our metal door machines as well as solutions and services.