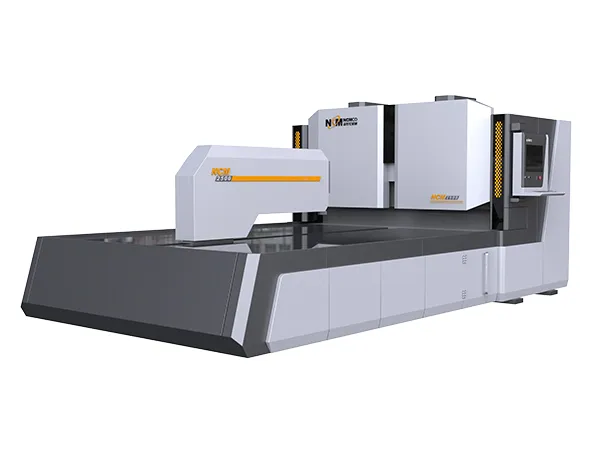

NCMCO has 26 years of experience in the metal door machine industry, we are happy to advise you from the selection of machines to the set-up of production line.

Automatic Steel Door Hot Press Machine

Through-feed hot press for bonding up to 8 layers of metal sheets for steel door panel production

Automatic Steel Door Hot Press Machine

Through-feed hot press for bonding up to 8 layers of metal sheets for steel door panel production

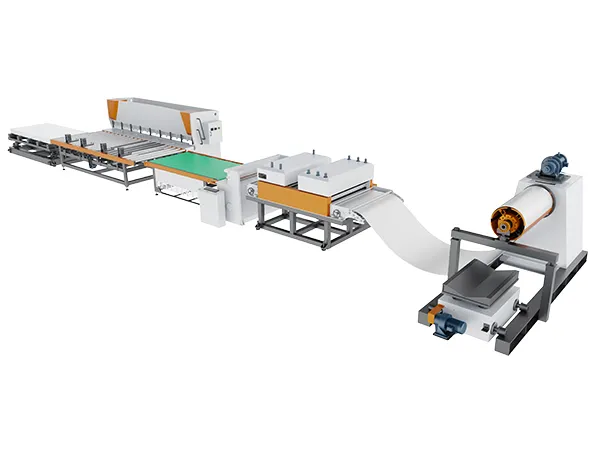

Automatic steel door hot press machine achieves uniform heating of metal door panels through the circulation of heat-conducting media such as hot water or thermal oil. The temperature can reach 85℃ to ensure a durable and reliable bonding effect. It features a fully automatic operation process and can handle 6 to 8 layers of lamination. Customization of bonding layers and dimensions is also available according to specific requirements. This steel door hot press machine operates in a single-piece flow mode, capable of processing 8 to 15 doors simultaneously, thereby enhancing production efficiency. Widely used in the steel door industry, this equipment provides manufacturers with an efficient and dependable lamination solution.

Security doors

Security doors Fire-rated doors

Fire-rated doors Healthcare/hospital doors

Healthcare/hospital doors Cleanroom doors

Cleanroom doors

| Number of gluing layers | 6-8 layers,customizable |

| Maximum opening distance | 200mm |

| Positioning block | 40-70mm,customizable |

| Grooving method | Upper/lower/No (optional) |

| Pressing platen temperature | Hot water of 80℃,thermal oil of 120℃ |

| Pressing efficiency | (30-55) S/P |

| Thermal conductive medium | Hot water,steam,thermal oil |

| Total power | 17-25kw (excluding heating device) |

| Control system | Delta/Siemens (optional) |

- Fully automatic feeding, glue spreading, and discharging can be achieved, enabling independent circulation.

- All processes can be completed on the machine, eliminating the need for additional space and minimizing dowtime.

-

-

-

Feeding Conveyor

Servo motors are used to ensure smooth operation, anti-interference, and multiple control modes.

Rollers made of high-quality materials (rubber, silicone, polyurethane) offer noise reduction, strong load-bearing capacity, smooth operation, and wear resistance.

The body adopts pull welding process to further improve the stability of the body connections and increase the service life.

-

-

-

-

Feeding Lift

The machine body is welded from 4mm thick steel plate, the platform is processed by gantry milling, and the body undergoes anti-corrosion and rust removal treatment, with the entire body sprayed with anti-rust paint.

Automatic lifting: the door panels are pushed using a belt conveyor, without the need for manual operation.

-

-

-

-

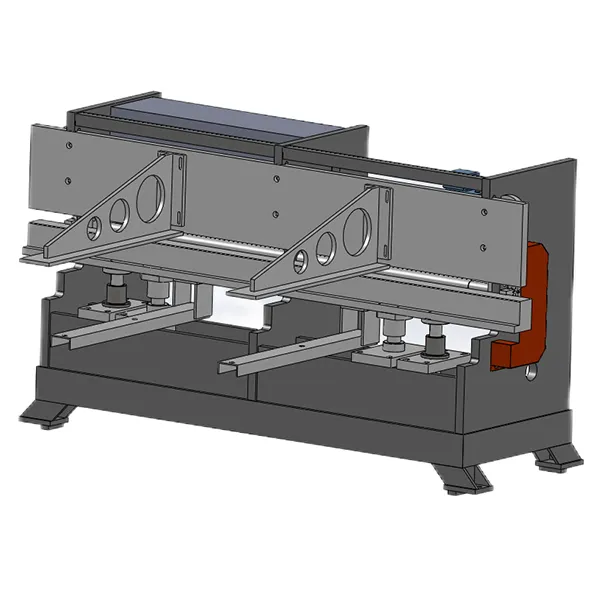

Hot Press

Q235 heating platens are used for good pressure-bearing performance, more uniform heating, and longer service life.

A new integrated hydraulic system is used, with an accumulator control system.

Bonding multiple layers of large flat steel plates, eliminating concerns about warping and deformation during door lamination.

A forced air cooling system reduces the working temperature of the hydraulic system.

Multiple heating medium configurations are available.

-

-

-

-

Discharge Lift

The machine body is welded from 7mm thick steel plate, the platform is processed by gantry milling, and the body undergoes anti-corrosion and rust removal treatment.

Automatic lifting: the door panels are received using a belt conveyor, without the need for manual operation.

Functions for material retrieval use belt conveyor and door-holding retrieval methods.

-

Our team of engineers will answer all your questions regarding our metal door machines as well as solutions and services.