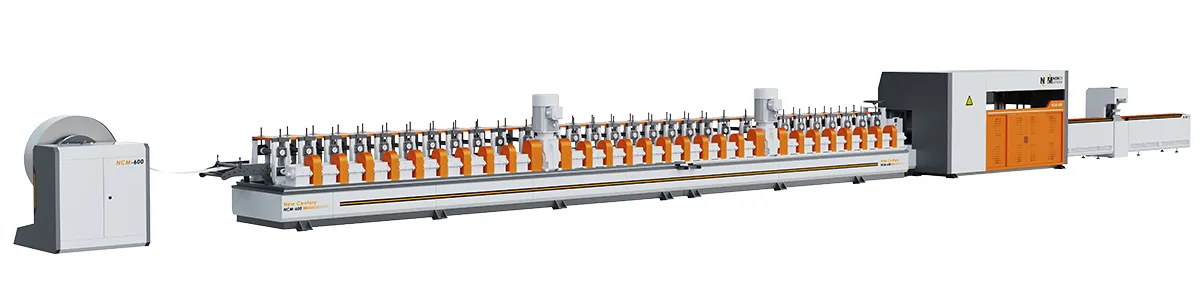

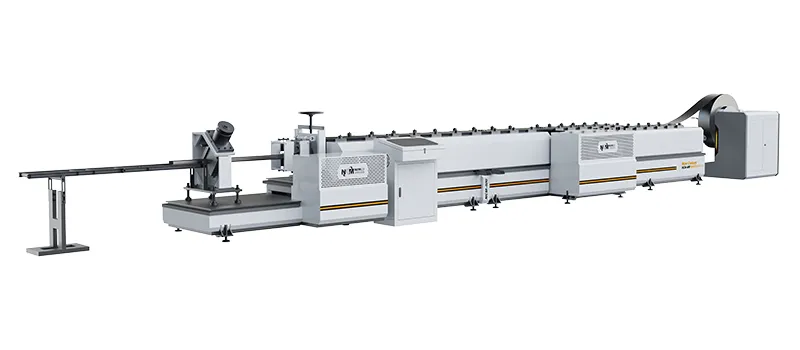

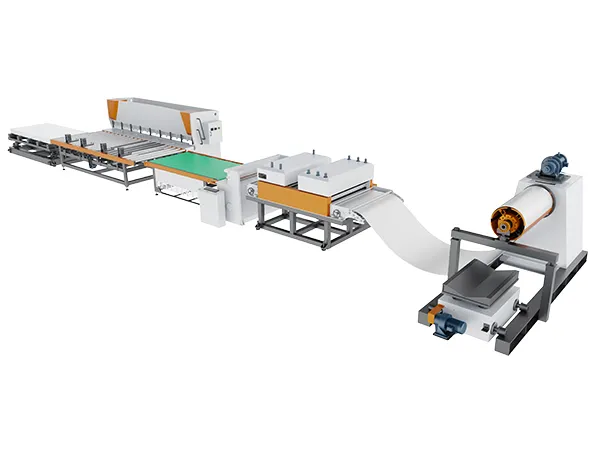

Automatic Steel Door Frame Production Line

Integrated system for automatic production of metal door frames with post-punched holes

Automatic steel door frame production line utilizes cold bending to achieve one-step shaping of various types of steel and stainless-steel door frames. Through hydraulic punching and shearing, it automates the process of hole formation and section cutting. This metal door production line adopts a post-punching technique, which avoids situations where certain holes cannot be punched or deformation occurs during the shaping process. By performing the shaping process before punching the holes, it minimizes changes to the roll forming machine, making it easier for customization of individual machines in the production line. Additionally, we offer two options for material storage: storage devices and pits, depending on your specific requirements.

| Model | ||

| Material thickness | 0.8~1.8mm,customizable | 0.8~2.0mm,customizable |

| Material width | 0~8m/min,adjustable | 0~10m/min,adjustable |

| Production speed | 100~400mm,customizable | |

| Total power | 20-45kW (depending on product configuration) | |

| PLC system | Delta/Siemens,optional | |

| Material storage (optional) | Storage device:No need for foundation construction,convenient for subsequent equipment relocation. Pit:Large storage capacity,maximizing the production efficiency of molding machines. | |

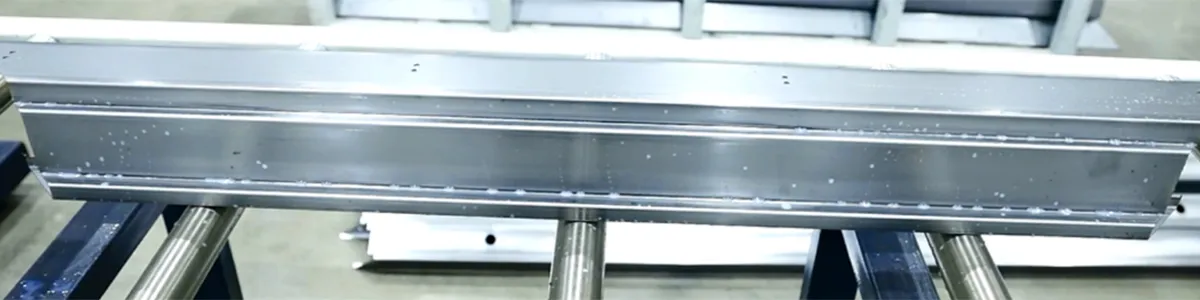

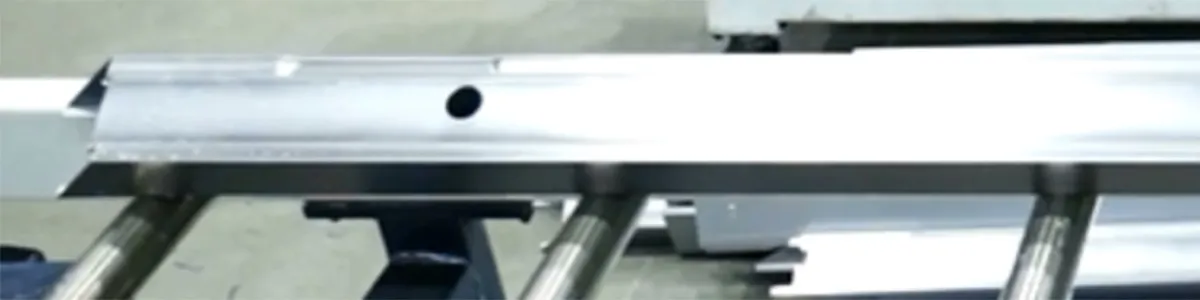

Security doors

Security doors Fire-rated doors

Fire-rated doors Healthcare/hospital doors

Healthcare/hospital doors Cleanroom doors

Cleanroom doors

-

-

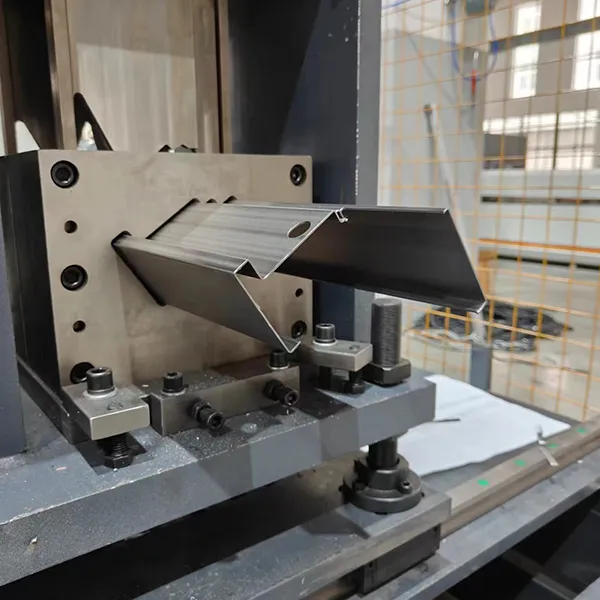

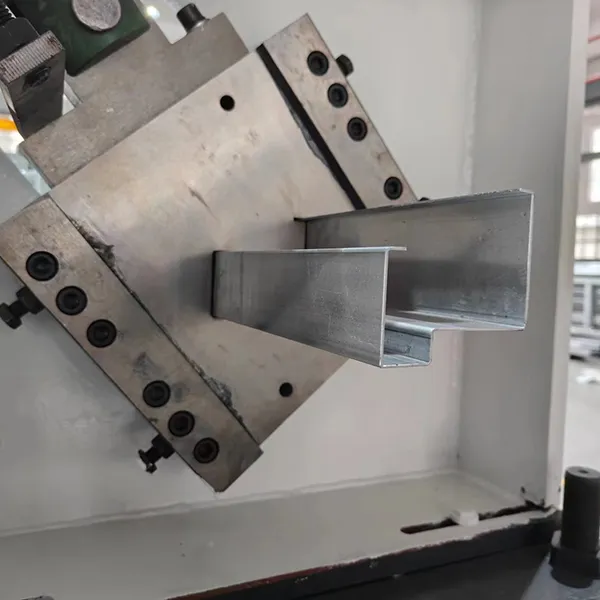

Post-punching Machine

Straight cutter (mainly used for flat cutting of door frame sections) / step knife (mainly used for step shaping of door frame sections) / circular knife (special process auxiliary) can be freely combined according to section requirements, and one machine can complete the processing of different cross sections of the same frame type.

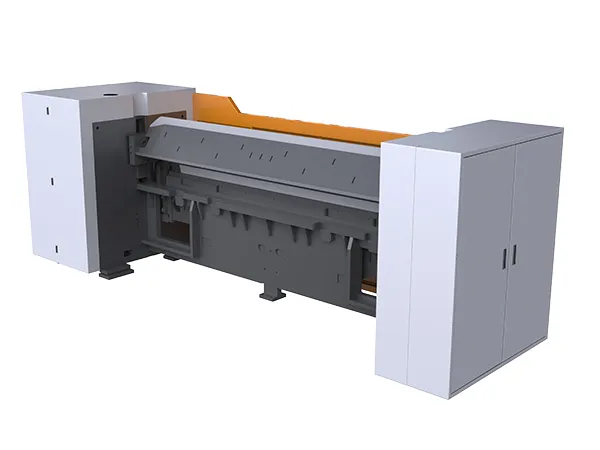

Roll Forming Machine

Our team of engineers will answer all your questions regarding our metal door machines as well as solutions and services.