NCMCO has 26 years of experience in the metal door machine industry, we are happy to advise you from the selection of machines to the set-up of production line.

45-Degree Hydraulic Shearing Machine

Hydraulic shear for cutting 45 degree corners of metal door frames

45-Degree Hydraulic Shearing Machine

Hydraulic shear for cutting 45 degree corners of metal door frames

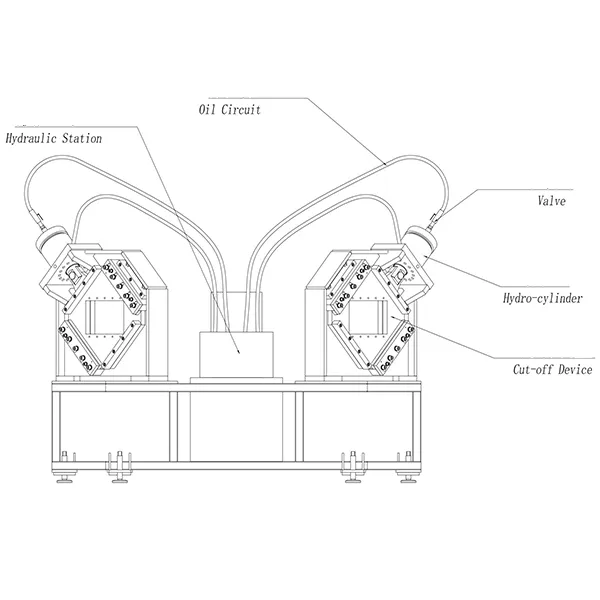

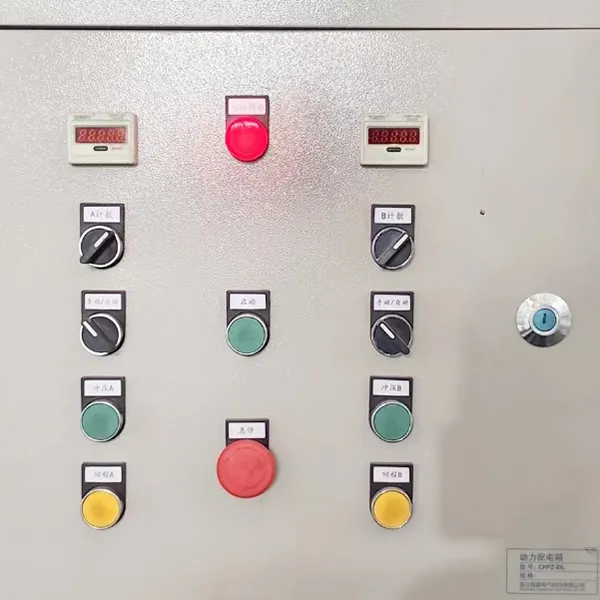

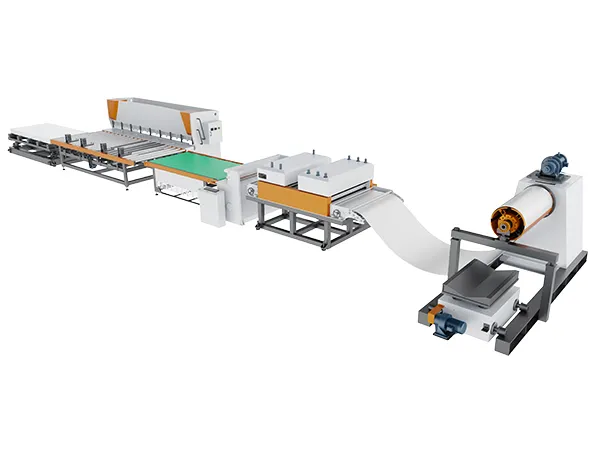

The door frame shearing machine includes hydraulic shearing machines, which adopts fully automatic hydraulic punching and shearing technology, achieving 45° corner cutting through hydraulic cutters. With single-head, single-mold and single-process, there is no need for too much debugging period. By introducing intelligent control systems and advanced laser technology, the production efficiency is improved, and it provides manufacturers with more production choices, allowing them to create more unique and innovative door frame products. Steel door frame shearing machine is suitable for traditional door frames, as well as special-purpose door frames such as fire-rated doors and corrosion-resistant doors, providing more possibilities and market competitive advantages.

45-degree hydraulic shearing machine uses fully automatic hydraulic shearing technology to achieve 45° corners cutting of various types of steel and stainless-steel door frames through the hydraulic cutting blade. With a single head, single mold, and single process, there is no need for extended debugging periods as the equipment can automatically punch and shear.

| Cutting force of right blade | 30kN |

| Cutting force of left blade | 30kN |

| Rated hydraulic pressure | 16MPa |

| Main power | 7.5kW |

| Dimensions | 2350*2200*1350mm |

- Automatic mold punching, ensuring more precise hole punching.

- A single head, single mold, and single process requires no need for extended debugging periods.

-

-

-

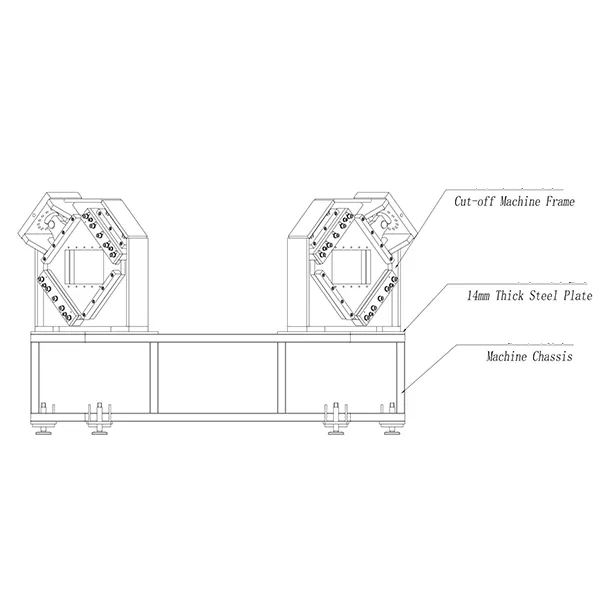

Machine Body

The main machine frame is welded by square tubes, and the welded structure has undergone professional stress analysis.

The cut-off blade holder is placed at a 45° angle, requiring no angle adjustment.

A 14mm thick steel plate is added between the cut-off blade holder and the lower machine frame to ensure a level cutting surface.

The design includes a left and right frame, which allows for welding after shearing without the need for secondary processing.

The machine frame has reserved positions for hydraulic station and electrical control system.

-

Our team of engineers will answer all your questions regarding our metal door machines as well as solutions and services.